Becric Casino Review

You don’t have to go sarhad paar to legally make your sports wager on a safe online platform anymore. Becric is a bookmaker and casino site that has worked hard for over a decade to be able to provide Indian customers with local, secured online sports betting.

It’s a secure environment where customers may wager on over 60 different sports without a single worry.

The aesthetics of the site make it quite uniquely Indian, and navigation is made simple too. Becric’s site is neatly organised, with links to each section easily accessible from the navigation bar. The website’s ‘Register’ and ‘Login’ buttons are located in the upper right corner of the page. The webpage is written exclusively in English and doesn’t just cater to Hindi speakers.

Becric’s headquarters are in India; however, the company was approved to run an online casino in India only after it received a licence in the Philippines. After nine years online, in 2020, the site finally offered cricket betting to the Indian audience. A large number of gamblers were drawn to its website within two years, thanks to its extensive library of casino games and enticing promos.

Planning to sign up? Here is an all-you-need-to-know Becric review.

Popular Slots Becric Casino

Among all the games available at any casino, slots are universally regarded as the most exciting. Many of the most played slot machines from the industry’s top developers can be found in the Slots section of the Becric Casino. In this list of games, however, you have two options!

Since the site does not have a search bar or other filter options apart from the provider filter, it only makes sense to search for games based on popularity and how new they are. Most slots go through the regular wear and tear of the customer demographic on the platform. These games, as they trend among users, fall in the popular slots category.

Here, you will find games like 777 Multi Hot 5, Spin X, Juicy 7, and many more. All the machines are produced by high-end, reliable software providers and follow similar guidelines while making the games. You can expect to play games with medium to low volatility, great return-to-player percentages, and amazing visuals.

On an odd day, you will also find bonuses for specific slot machines that will allow you to revisit a machine you may not have played in a while.

New Slots Becric Casino

On the other hand, the slot machines that were just recently manufactured and distributed into the market are known as the new Becric slot machines. Consumers of Becric Casino have the opportunity to get their hands on incredible new games such as Pearls of India, Aztec Slots, and Burning Ice before those games are released to customers of other casino marketplaces.

Becric encourages you to use their platform to try out these things and enjoy them as much as possible. To ensure you do, new Becric promo codes and bonus codes are frequently made available on the platform to draw attention to newly added slot machines. You may anticipate that the machines will, like the most popular games, have non-biased random number generator methods built into them. Additionally, you can anticipate that the machines will have a high return to player percentage and modest volatility.

Slot machines are an excellent alternative to the more complicated table games that are offered on Becric. But before you try out a new game, make sure you test out the demo version to get the hang of the game prior to wagering real money.

Becric Aviator

Becric Casino allows you to play Aviator, which is a revolutionary game within the online gambling sphere. It is a new game, but the novelty of the system led to a huge burst in popularity which is yet to wear off! Becric Aviator is a simple game where the screen shows a plane taking off from an airport, and as it climbs, the reward grows. It is quite a thrilling game for those who are into trying something new.

The interesting part about Becric Aviator is that because it is so different from any kind of casino game that came before it, nobody really knew under what category it should fall. Therefore, in order to give it the most exposure, it was published under the category of online slots – despite having nothing to do with slots. There are no paylines in Aviator, which is half the reason why it got so popular. And with slots being the most popular online casino gaming category, it got a lot of eyes on it from the very beginning.

What you need to do to be a successful player is to keep your greed in check and cash out when the going is good. You can also play the game on your Becric app with a simple Becric Aviator download.

Aviator Game Rules

In Becric Aviator, you take on the role of a daring pilot, with rewards based on how high you manage to fly your plane. Your winning bet will be multiplied by a coefficient, which is the same as the height.

The key to the Becric Aviator game is to avoid going too fast and to be able to brake at the ideal time during take-off. To put it roughly, the multiplier will stop growing if you don’t press the buyback button before the plane stops climbing.

If the rise ends before the bet is cashed out, the money is lost. Sorry, you finished last. If you can control your greed and accept a rate multiplied by two or three, you will succeed!

Quick rules:

- The win multiplier increases from 1x to 2x as the aeroplane climbs;

- Your cashout chances determine your prize. Before each round, an RNG selects the coefficient at which the aeroplane departs;

- Multiply the percentage of success by your wager. Use the game’s features to make rounds fair.

Finally! Cash-out before the plane crashes to earn your winnings!

Becric Sports Betting

Since they have finally been able to provide the Indian audience with cricket betting after a 9-year-long hiatus, you can expect to be bombarded with cricket tournaments from around the globe. Every major cricket tournament, both at the domestic and international levels, and every cricket match played in India can be bet on at Becric. They weren’t kidding with the name, after all!

It comes as no surprise that Becric is a fan favourite. You can wager on tournaments, including:

- Twenty20 World Cup;

- The Ashes;

- ODI Matches;

- And, of course, the IPL.

Each match will feature numerous bets, allowing you to wager on a wide variety of outcomes. You can bet before and during the match, too. Most importantly, customers can also enjoy watching the match on the platform.

But that’s not all. In the country with the largest population in the world, cricket isn’t the only sport followed. Customers will find a wide range of sporting options but keep in mind that the more prominent ones are Indian favourites. This means that kabaddi, football, tennis, and hockey are all available as betting options.

But surely, that’s not all.

Becric Exchange

Becric isn’t just a sportsbook. If you’re not a fan of betting, you can always play casino games. Becric Casino provides players with an exciting gaming experience. As a result, it has formed alliances with reputable software developers so that every customer can enjoy their preferred gaming experience. Providers guarantee that their games work smoothly on a wide variety of platforms. In addition, Becric prioritises providing players with high-definition visuals and video.

This platform also offers the thrilling option of live casino to its Indian user base. Gamblers can interact with real people through a live stream in the live casino section of Becric. The real-time content features HD visuals and audio. They make playing games easier and allow players to compete against a dealer. Players at Becric can get a good look at the action from all angles thanks to the plethora of cameras set up throughout the venue. The exciting action is waiting for you; all you have to do is choose a live table.

Just be sure to double-check for bonuses on the game of your choice and to read the fine print to get the most out of your winnings!

Table Games

You can play a variety of table games at this casino, including roulette, poker games, blackjack, baccarat, game shows, and more. There are multiple options for every feasible interest. Lightning Roulette, Immersive Roulette, Auto Roulette, Speed Roulette, and dozens more variants of roulette are available to players.

Casino staples like roulette, baccarat, blackjack, and poker get most of the attention, but there is a ton of games to choose from in the “other” and “game show” sections. Super Sic Bo, Dream Catcher, Deal or No Deal, and Monopoly Live are just a few examples of the exciting games available at Becric Casino.

Customers can filter the games based on ‘Hot’ and by the provider. If you want to know what is trending among other customers, head over to the Hot section. If you’d rather play games by, say, Turbo alone, click on it and find games by their team. Other games include:

| Game | Provider |

| Neko | Turbo |

| Aviator | Spribe |

| Blackjack double exposure | PNG |

| Deuces wild Power Poker | MG |

And many more. The games are notorious for being accessible and of high quality whether you choose to play on the desktop browser or on your smaller screen gadgets.

Indian Special

Indian gamblers enjoy a wide variety of table games, from blackjack and baccarat to slots and craps to video poker and roulette to more localised favourites like Andar Bahar, Passa, Paplu, Flish, and Teen Patti. It’s no surprise that Indians like a nice game of cards. And Becric Casino has a good range of options to choose from.

We can’t have an Indian sportsbook without cricket, nor can we have an Indian casino without Teen Patti and Rummy! Playing Rummy is no longer just a weekend family night activity. You can now play it en route to work while stuck in traffic or while you wait for your 4 o’clock chai. Go to the Indian Specials section of the games on Becric, and you will have access to them all.

- Win Go;

- Teen Patti;

- Rummy;

- AB Pairing;

- A Vs. B;

- And Pool Rummy!

If you aren’t one to be satisfied playing against the machine, head over to the live section, and you can play Teen Patti and Andar Bahar against a live dealer! There’s still a way to go before you can play in a regional language, but we’ll take the win.

Becric Registration

You’ve finally decided to give betting a shot, so it’s important to familiarise yourself with the proper order for doing so. Simple account creation at Becric registration is all that’s required. Here is a straightforward procedure that will get you an official Becric account in no time:

Take a look at Becric Casino’s main site. Any web browser will do for accessing the site. When you get to the main page, select the “Register” button located at the top right corner.

- Fill in the information fields in the pop-up window;

- You’ll be asked for some personal information before you can place a wager, including your first and last name, email address, phone number, country of residence, age, your preferred currency for deposits and withdrawals, date of birth, gender, and preferred language;

- The final step is crucial, but one that most people skip: read the platform’s terms and conditions before confirming.

Done with the Becric registration process? Next, complete the KYC. An email with a verification link will be sent to your address. Click the button and fill in your account details. You will then receive a link when your account has been verified.

Becric Login

Yes, registration and login are different. You will have to log in to access your account, make wagers, play casino games, and so on. So how do we perform the Becric login? Remember the username and password you set for your account? If not, keep them handy.

- Access the Becric bookie’s main website;

- The second step is to click “Sign in,” which appears next to the “Register” button in the top right corner of the page;

- Third, complete providing any details that were missed out during the registration process;

- In the new window that appears, type in the username and password you chose when you registered for the site;

- Verify that you are not a robot;

- Click Enter for the Becric login!

You will automatically log into your game account after completing these steps. Your account can still be accessed, even if you have forgotten your password, by clicking the “Forgot password” link and following the instructions provided.

If this is your first Becric login, don’t miss out on the welcome bonus!

Becric Sign Up Bonus

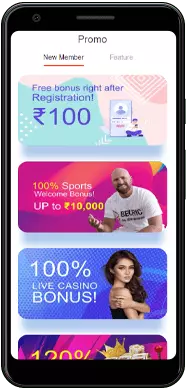

Various bonuses and special offers give Indian players a chance to increase their bankroll and boost their winnings. The Becric sign-up bonus is the very first bonus you will receive, and it is split between the Sportsbook and the Casino.

| Section | Bonus |

| Casino | You can, of course, select the Casino Welcome Bonus if you’re a fan of casino gambling. A minimum deposit of INR 500, a maximum bonus of INR 5,000, and a 25x rollover apply to this bonus. Don’t forget the bonus of 120%! |

| Sports | Get a bonus of over 100% up to INR 10,000. With a minimum deposit of INR 500, you can get a maximum bonus of INR 5,000! Wondering how many times you have to roll over? Only 10. |

| Live Casino | Not a lot of casinos provide a live casino welcome bonus, making Becric special. Get a bonus of over 100%, with a minimum deposit of INR 500, a maximum bonus of INR 5,000 and a 25x rollover! |

When it’s withdrawal time, simply cash out to your desired source!

FAQ Becric

When did Becric launch in India?

Becric was launched in 2013, but only recently was it able to provide cricket betting to the Indian audience.

Can Becric be trusted?

In a word, yes. Modern security protocols, such as SSL encryption, are integrated into the Becric platform to protect users. That way, all of Becric’s casino goers can rest easy.

How do I register with Becric?

Head over to the website and click on the Register button located at the top right corner of the main page. Fill in your details, submit the necessary KYC documents and start playing!

How do I get a sign-up bonus?

As soon as you log in to your Becric account for the first time, a pop-up will offer you a choice of welcome bonuses. You can use them for sports betting, casino games, or live casino games.

How do I start playing at Becric Casino?

Once your account has been verified, and you’ve logged in, you will have to make a deposit. You have to spend money to make money! After adding funds to your account, you can go ahead and pick a game to play or a sport to bet on!